Concrete Sealer or Densifier? Selecting the Right Solution for Your Warehouse Floor

- The Field Foreman

- Jul 18, 2025

- 3 min read

Updated: Aug 3, 2025

When it comes to maintaining a warehouse floor, choosing between a concrete sealer and a concrete densifier can be crucial. This decision impacts dust control, visual appeal, and budget. In this blog post, we will compare lithium-silicate densifiers, such as Pantheon 273 CF, to topical sealers. By the end, you will understand which product is best suited for your warehouse environment.

Understanding Concrete Sealers and Densifiers

Before we get into the details, let’s clarify what these products do.

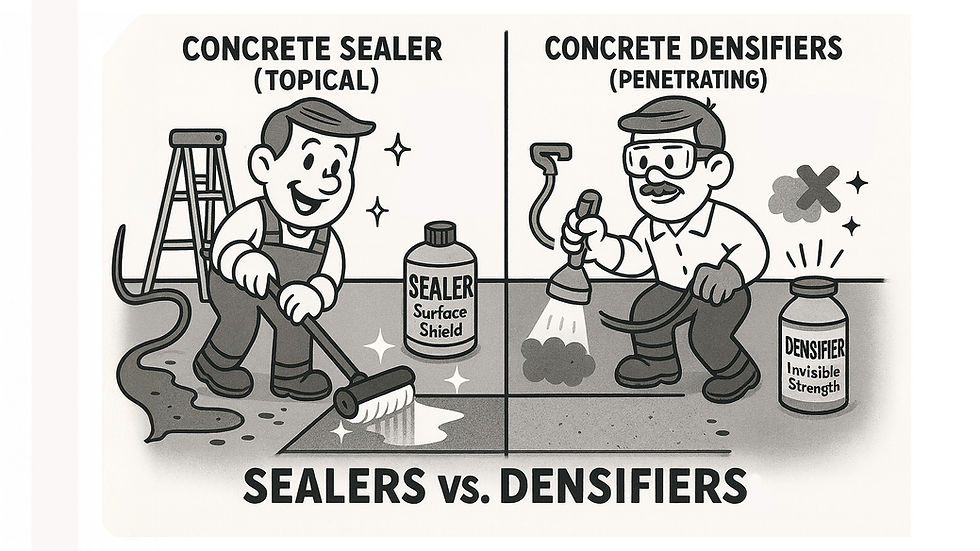

Concrete sealers are surface coatings applied to protect concrete against stains, spills, and wear. They improve aesthetics by providing a glossy finish and can simplify cleaning. For example, certain sealers can enhance gloss levels by 20-50%, making floors look polished and new.

On the other hand, concrete densifiers, especially lithium-silicate options, are absorbed into the concrete. They chemically react with the concrete, filling pores and increasing density. This leads to better dust control and strengthens the concrete without changing its surface look significantly.

Both options offer unique advantages. The right choice will depend on your specific warehouse needs.

Dust Control

Dust is a key issue in warehouse environments. It can reduce air quality and increase cleaning time, which is especially concerning in busy operations.

Concrete Sealers

Topical sealers create a protective barrier that can help reduce dust by preventing fine particles from escaping. However, this top layer can degrade over time, especially in high-traffic areas, ultimately requiring more frequent reapplications. For instance, a standard concrete sealer might need reapplication annually or every few years, depending on traffic.

Concrete Densifiers

Densifiers excel in controlling dust. They penetrate deeply into the concrete, locking dust particles in place and reducing airborne dust by up to 90%. This results in a cleaner work area and can lead to increased comfort and health for employees.

Gloss and Aesthetic Appeal

The visual appearance of your warehouse floor is another significant factor.

Concrete Sealers

If a shiny finish is important, topical sealers can deliver that. Available in finishes ranging from matte to high gloss, these sealers can elevate the overall look of your warehouse. For example, applying a high-gloss sealer can increase light reflectivity by 60%, enhancing overall lighting.

Concrete Densifiers

Densifiers don’t provide a glossy finish. They maintain a more natural appearance of the concrete, which some may prefer for an industrial look. While they may lack shine, the durability they offer can lead to a floor that looks good over time with less maintenance.

Budget Considerations

Budget constraints will also influence your choice.

Concrete Sealers

Topical sealers are often cheaper initially but may require more frequent applications—especially in high-traffic areas. Over time, this can lead to higher costs. For instance, a sealer may cost $0.50 to $1.50 per square foot initially, but re-application could double that cost every few years.

Concrete Densifiers

While lithium-silicate densifiers typically have a higher initial cost, around $1.50 to $3.00 per square foot, they often lead to lower long-term maintenance costs. Their durability means fewer applications, helping to save money over time.

Decision Matrix

Here's a summary to help you make your decision:

Criteria | Concrete Sealer | Concrete Densifier |

Dust Control | Moderate | Excellent |

Gloss | High | Low |

Initial Cost | Low to moderate | Moderate |

Long‑Term Costs | High (due to reapplication) | Low (more durable) |

This matrix will serve as a visual guide to assess the benefits and drawbacks of each option against your warehouse's needs.

Application Methods and Considerations

Understanding how to apply these products can assist you in making an informed choice.

Application of Concrete Sealers

To apply a concrete sealer, ensure the surface is clean and dry. You can use a roller, brush, or sprayer for application. Regular maintenance is necessary, as even the best sealers will need to be reapplied, especially in busy sectors.

Application of Concrete Densifiers

Applying densifiers is simpler. They require a clean surface and can be sprayed or poured directly. After application, allow them to penetrate the concrete for a specified curing time. This approach demands less ongoing maintenance, making densifiers a popular low-maintenance choice.

Weighing Your Options

Deciding between a concrete sealer and a densifier goes beyond preference. You need to consider your warehouse's specific conditions and requirements.

If dust control is crucial and you want to cut down on airborne particles, a concrete densifier is likely the best option.

If aesthetics and gloss are vital to your operations, a concrete sealer may suit your needs better, but be prepared for ongoing maintenance.

If you have budget constraints, consider the long-term costs associated with both choices. Although densifiers might cost more initially, their lower maintenance could lead to savings over time.

In conclusion, understanding the advantages of each product will help you make a well-informed decision, ensuring your warehouse floor meets your safety, aesthetic, and financial goals.

Explore Pantheon 273 CF for more information on lithium-silicate densifiers, and do check out our selection of topical sealers for aesthetic options available for your warehouse floor.